Do you need to show animating cylinder i.e. increasing or decreasing height of a cylinder. Then here is a quick and easy way of doing that. Please note that you can use any unit system (metric or inches) for this tutorial.

1. Start a new part and save it without creating any features or sketch in it. I would call this part as Dummy part.

2. Start a new assembly and save it as Animating Cylinder.

3. Insert the part into this new assembly using Insert Component option (Insert > Component > Existing Part/Assembly)

4. Browse to the part location and drop the part anywhere in the assembly or simply click on OK.

5. If you notice a (f) part name in the assembly in front of manager tree, then right click (RMB) on it and select float from the list. The (f) indicates that part is fixed which means it can make any movement. But as we need to move the part, we need to make it free. Hence we selected float. Now the part can move in any direction.

6. The (-) in front of part name indicates that part is free to move/rotate anywhere.

7. Now select Front planes of the assembly and of the dummy part and add a coincident mate.

8. Select Right planes of the assembly and of the dummy part and add a coincident mate.

9. Add a distance mate of any value (say 10 mm) between the Top planes of the assembly and of the dummy part. You may have to set the position of Top plane of Dummy part as required. Use Flip dimension to set to the position.

10. Start a new part within the assembly (i.e. in context modeling). With the options coming up in new versions, you can save the file internally in the assembly itself. Insert > Component > New part.

11. Click or select Assembly Top plane to start the sketching for new part. You’ll notice a change in the pointer.

12. Now you’ll be the part edit mode and further in the sketching mode. Create a circle with center at the origin and of any diameter.

13. If you feel/require, you can dimension the circle. As a best practice and good habit, it’s always better to use a fully defined sketch. I have given a diameter of 80 mm.

14. Now click on Extrude Boss/Base or Insert > Boss/Base > Extrude.

15. You’ll a see a preview of the extruded cylinder. Click on Direction 1 and then select “Up to Surface” from the drop down list for extrude end condition.

16. Now click in the Face/Plane selection box to define the face/plane for the extrude condition.

17. Expand the feature manager tree by clicking on the plus sign next to assembly name.

18. From the list, select Top plane of the Dummy part.

19. You’ll see the Top plane (Dummy part) in the Face/Plane box of extrude command. Click OK to exit the command.

20. Click on Edit component to exit part editing and move back to assembly editing.

21. This is how the screen will look like.

22. Now switch to Motion Study.

23. Drag the time to any time level/distance. I have set it to 6 sec.

24. Expand the Mate folder by clicking on the plus sign.

25. From the list, double click on Distance mate.

26. You’ll see dimension edit dialog box. Change the value to any value. I have set it to 50mm.

27. Click OK to save the current value and exit the dialog box.

28. You’ll now see the time bar (blue color) in front of Distance mate indicating the change in mate dimension.

29. Click on calculate. And then once calculation is over, you can see the cylinder growing. Use play button to play the animation.

30. You can set Playback mode to Reciprocate to see cylinder increasing and decreasing in size.

If you found this post useful, please share it!

5. Create a sketch on as shown in the pic (you may choose different values for the dimensions).

5. Create a sketch on as shown in the pic (you may choose different values for the dimensions). 6. Using revolve feature, create a cylinder and finally exit the part edit mode. You may save the part internally or externally as desired.

6. Using revolve feature, create a cylinder and finally exit the part edit mode. You may save the part internally or externally as desired. 7. Now insert the ball part (created in step 1) into the assembly. Place it any where in the assembly and make sure it is floating i.e. not fixed.

7. Now insert the ball part (created in step 1) into the assembly. Place it any where in the assembly and make sure it is floating i.e. not fixed. 8. Add two coincident mates (between front planes of ball and assembly and similarly between top planes of ball and assembly).

8. Add two coincident mates (between front planes of ball and assembly and similarly between top planes of ball and assembly).

9. Add a 1.6in value distance mate between right planes of ball and assembly.

9. Add a 1.6in value distance mate between right planes of ball and assembly. 10. Now switch to part edit mode and edit the long tube/pipe (created through steps 3-6). You can right click on the part in graphics or in the feature manager and select edit part.

10. Now switch to part edit mode and edit the long tube/pipe (created through steps 3-6). You can right click on the part in graphics or in the feature manager and select edit part. 11. Start a new sketch on the front plane of the pipe.

11. Start a new sketch on the front plane of the pipe. 12. Expand the feature tree for ball part and select the sketch used to create the ball.

12. Expand the feature tree for ball part and select the sketch used to create the ball. 13. Click on convert entities. This will copy the sketch used for ball onto the front plane of the pipe

13. Click on convert entities. This will copy the sketch used for ball onto the front plane of the pipe 14. Using horizontal line as centre line, create a revolved feature.

14. Using horizontal line as centre line, create a revolved feature. 15. Hide ball part for easy selection and further feature addition/editing. Right click on the ball part and select hide components.

15. Hide ball part for easy selection and further feature addition/editing. Right click on the ball part and select hide components. 16. Add a fillet of 0.25in as shown.

16. Add a fillet of 0.25in as shown. 17. Add a shell feature with 0.1in as wall thickness, shell outward and select both the ends of the tube under faces to remove.

17. Add a shell feature with 0.1in as wall thickness, shell outward and select both the ends of the tube under faces to remove. 18. Create another sketch on the front plane of the pipe (as shown) and do a revolve cut.

18. Create another sketch on the front plane of the pipe (as shown) and do a revolve cut. 19. Exit part edit mode. And finally save the assembly.

19. Exit part edit mode. And finally save the assembly.

2. Drag the timebar to any time value (I have set it to 10 seconds).

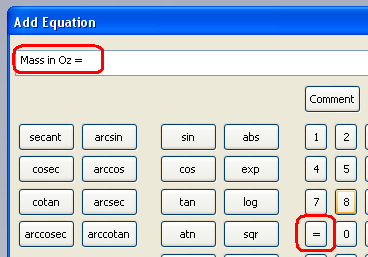

2. Drag the timebar to any time value (I have set it to 10 seconds). 3. Now double click on the distance mate mate. This will highlight the distance value and dimension modify window will pop up.

3. Now double click on the distance mate mate. This will highlight the distance value and dimension modify window will pop up. 4. Key the desired value (I have used 13.5in) and click OK to finish distance modifications.

4. Key the desired value (I have used 13.5in) and click OK to finish distance modifications. 5. Now hit calculate and then finally you can play/save your animation. Check the video under

5. Now hit calculate and then finally you can play/save your animation. Check the video under

3. Click on New View (add new view).

3. Click on New View (add new view). 4. In the Named View window, enter a desired view name.

4. In the Named View window, enter a desired view name. 5. Click OK on the Named View window. You can see the new view orientation in the view list. Finally close the View Orientation.

5. Click OK on the Named View window. You can see the new view orientation in the view list. Finally close the View Orientation.

2. Repeat Steps 2-5 as described above for creating the new sectional view orientation.

2. Repeat Steps 2-5 as described above for creating the new sectional view orientation.