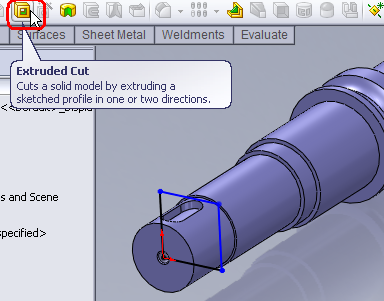

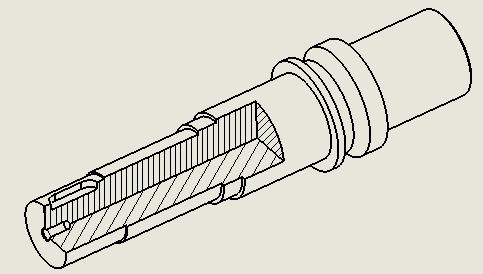

I’have been seeing lot of people talking on Geneva Mechanism over various forums and even I have been wondering myself on animating a Geneva Mechanism in SolidWorks. In the past I had used many different tricks to achieve it like gear mates or using surfaces etc.

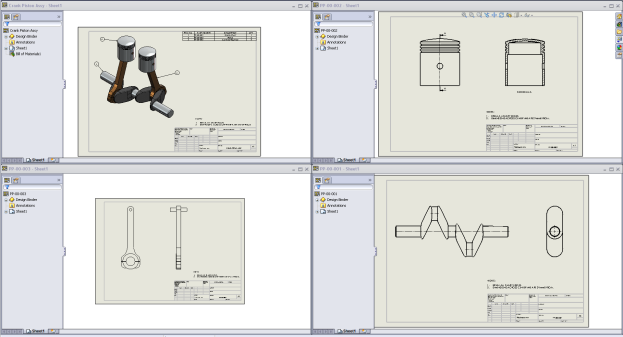

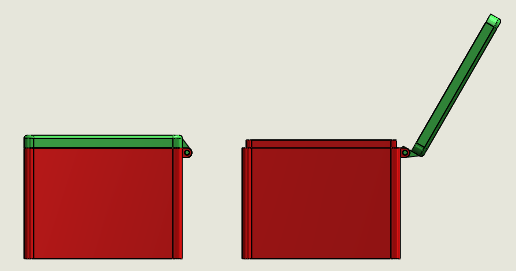

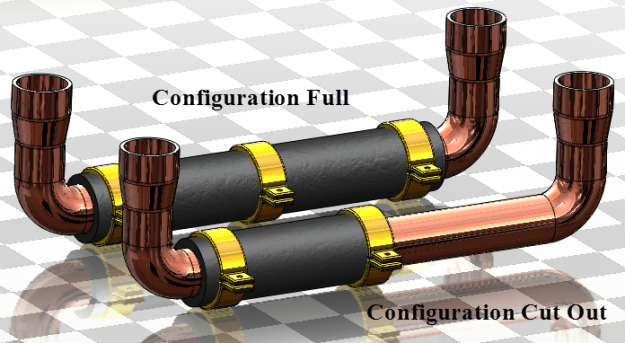

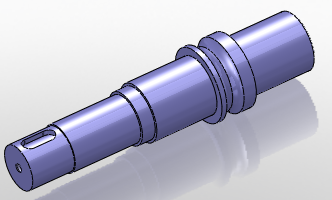

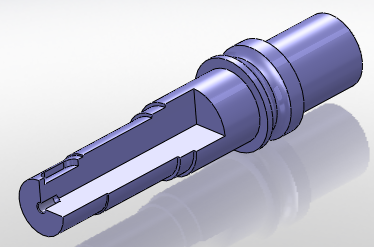

Here is an animated view of what I have done few days back. I have been modelling some simple file to put up for this post but I recently came across SolidWorks Geneva-Device files on GrabCAD by Bobby Dyer. I would like to thank him for allowing me to use his files to create this tutorial.

Based on the requirements Geneva Mechanism can be external or Internal:

You can download the files used for this tutorial here: SolidWorks Geneva-Device files. The important ingredient are Contact and Motion Study Properties

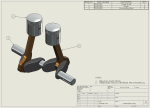

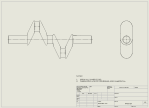

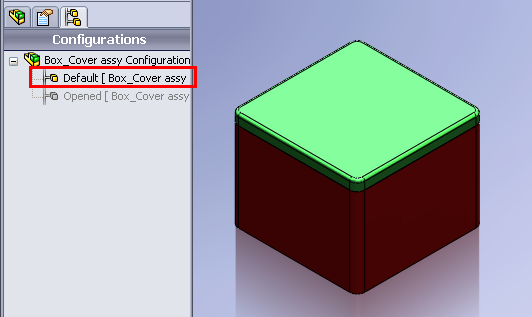

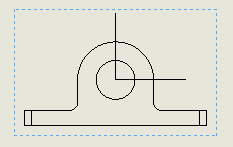

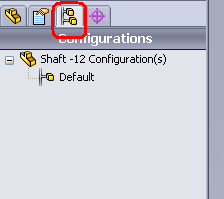

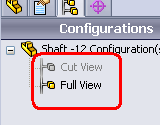

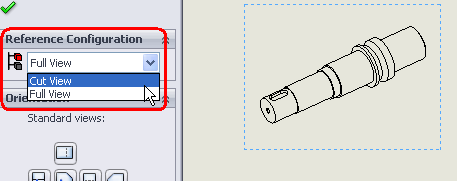

1. Open the “Geneva Device” assembly from the downloaded files.

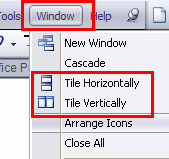

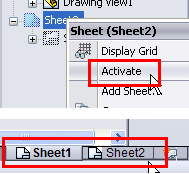

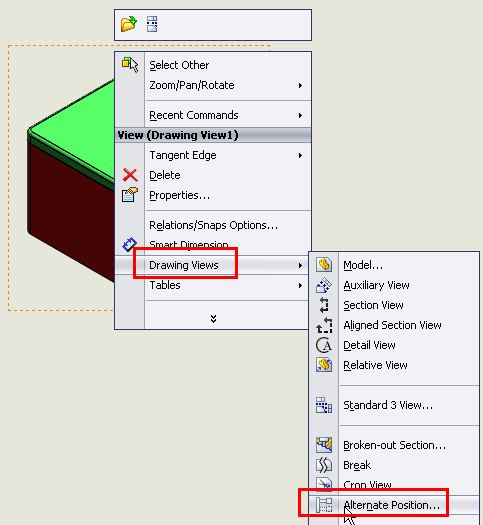

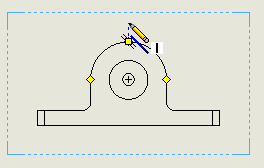

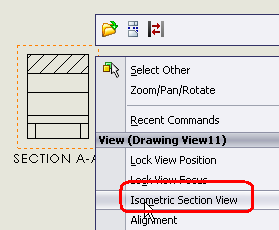

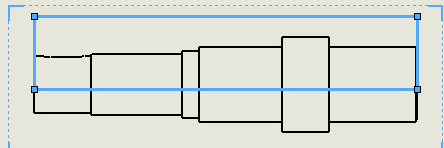

2. Switch to Motion study and set the model orientation as required.

3. Change the Motion study type to “Basic Animation“.

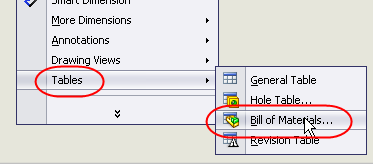

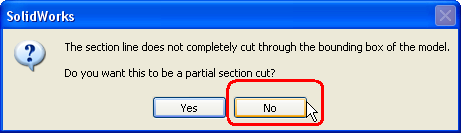

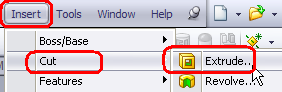

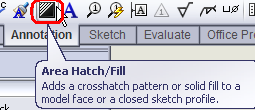

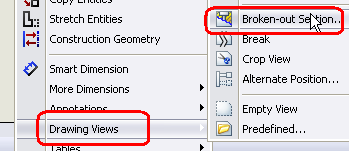

4. Click on “Contact“.

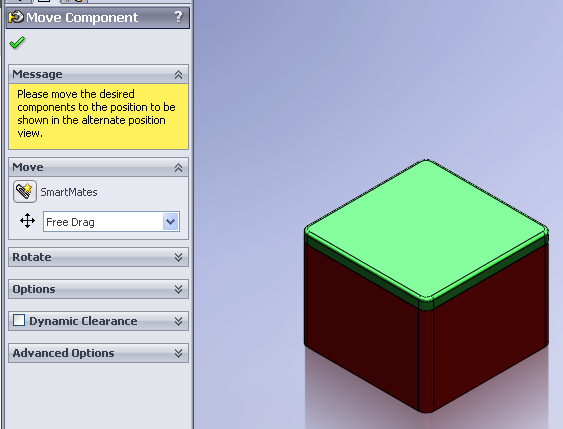

5. Now in the Contact property manager click on the pin to keep it visible as we need to use it twice.

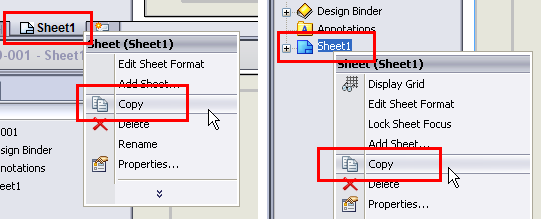

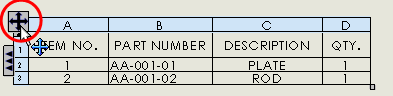

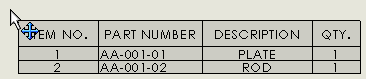

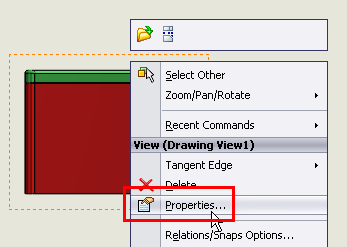

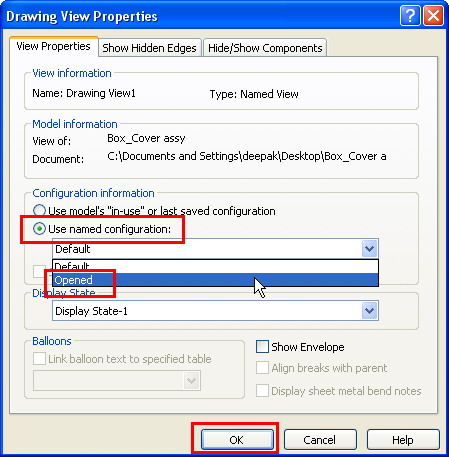

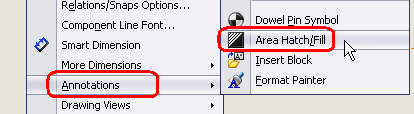

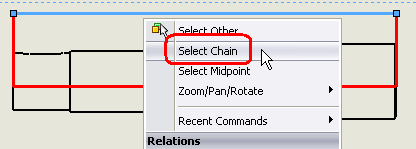

6. Now under components selection box, select “Index Wheel” and “Advance stop” parts.

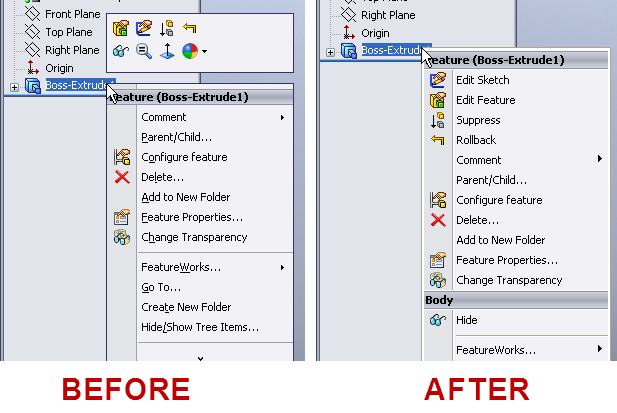

7. You can select them from graphic area OR from feature manager tree OR motion study tree.

8. Click OK to apply the contact.

9. With Contact property manager visible, select “Index Wheel” and “Indexer” parts and click OK to apply the contact. You can now close the Contact property manager.

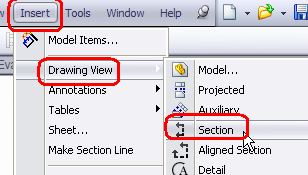

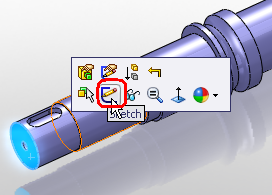

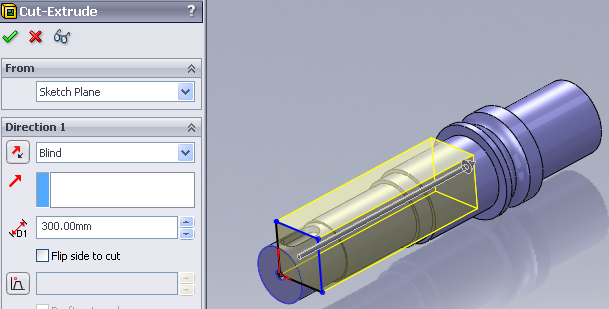

10. Click on “Motor“.

11. Set the motor type to “Rotary motor“. Select the cylindrical face or circular edge of “Index Wheel” or “Indexer” parts to define the direction of ( I have selected the cylindrical face of the Indexer). Set the motion function to “Constant Speed” and RPM to 30.

12. Click OK and apply the motor.

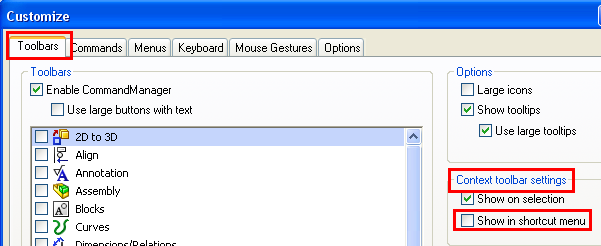

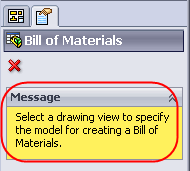

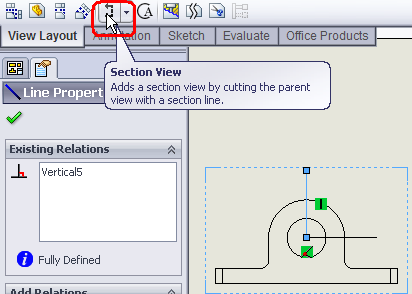

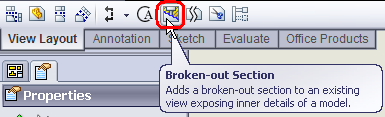

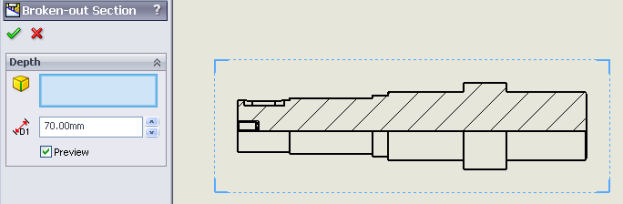

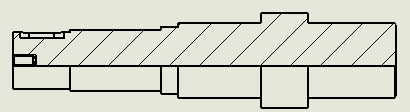

13. Now click on “Motion Study Properties“.

14. In the Motion Study Properties property manager under basic motion, set the frames per second to 30 (the larger number the more smoother motion) and set the Geometry Accuracy and 3D Contact Resolution settings to high side (move the sliders to right). This will make collision simulation more accurate and smoother motion, but requires more time to compute.

15. Click OK to set the properties.

16. Finally click on “Calculate“.

17. And now is the show time. Hit play to enjoy the show.

You can change and experiments with the settings to get a better animation. Click on save if you want to export the animation as AVI or series of pictures. You can change other settings in the save window.